It’s Necessary to Do Sample Test before Customizing the Protective Film

When customers look for a suitable supplier, they will consider price, production period, and payment terms into consideration. We prefer to get surface samples that customers need to protect before formal cooperation. We believe in that every surface is unique and the protective film customized according to each protected surface is the most suitable protective film for customers and our quality guarantee.

Customization Case of PVC Protective Film Customer

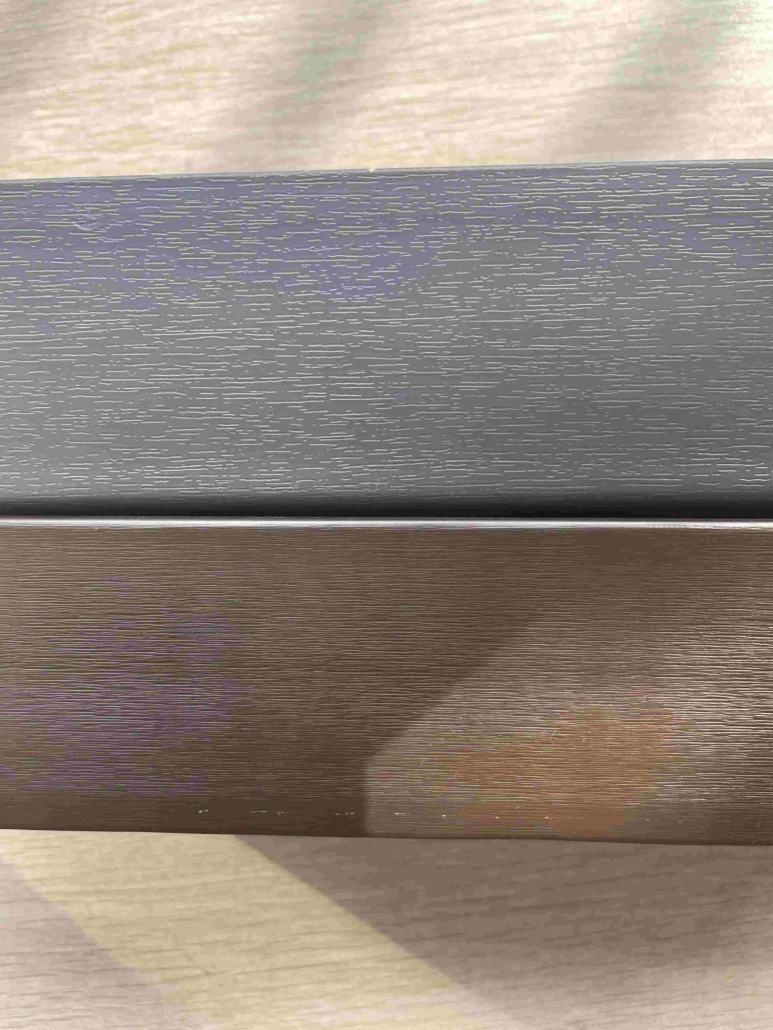

As a supplier of leading PVC profile manufacturers in China, such as Zhongcai Profiles and Conch Group, we have attracted many new customers with excellent quality. Customer A wants us to provide them with the same protective film as we supply to Conch Group. Before mass production, we suggest they supply their surface samples that need to protect to determine the final technical parameters. Like most customers, they think that PVC profiles with a smooth surface are similar and thought we can start production directly. After communication, they finally agreed to trial apply their interesting item on their profiles before production. Unexpectedly bubbles occur between the film and their PVC profile the next day.

To fix the problem, we consult Conch Group and they didn’t meet such a problem before. Our technical engineer carefully examined every step of our production process and found everything is normal. Custom sent us their protected surface sample and we examined it and finally figure out the problem. Although the surface of customer A’s profile is consistent with that of Conch’s profile, there is a substance called calcium carbonate added to their profiles, which would slowly releases air. As we only use high-quality PET raw materials, the aluminum is distributed evenly on the film, so the air can not penetrate. It is blocked by this aluminum layer, which leads to the formation of bubbles. After knowing this, we customized a batch of aluminized PET film for this customer and avoid the generation of subsequent bubbles. Since then, we maintains a good cooperative relationship with this customer.

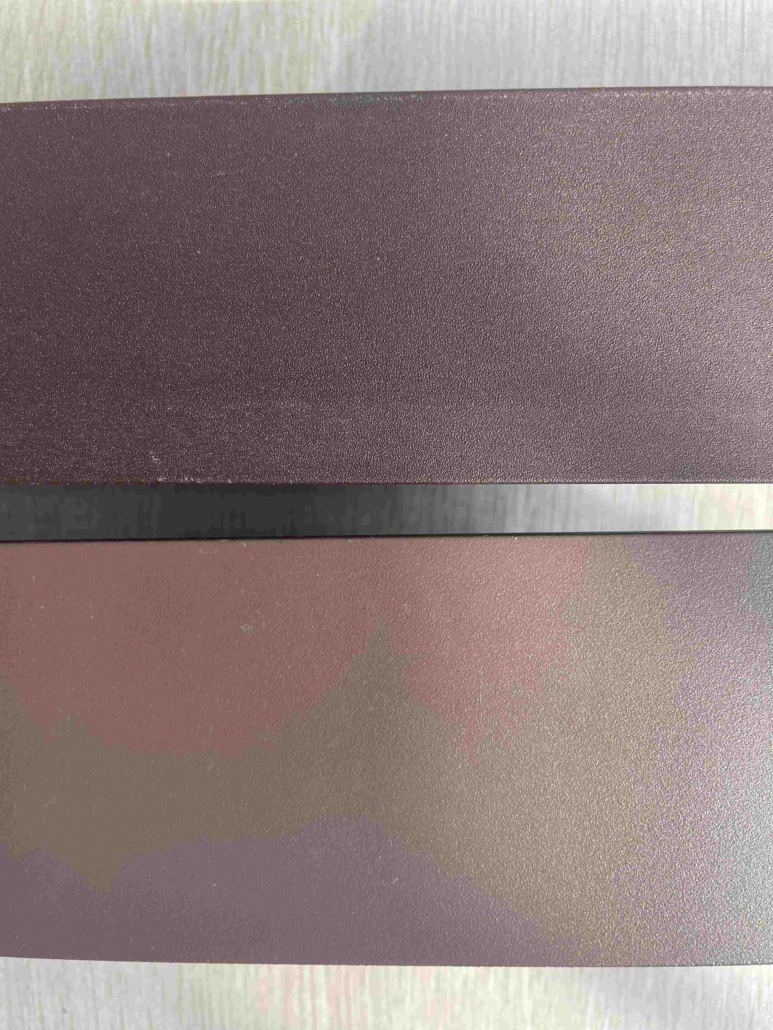

Aluminum profile manufacturers may encounter a similar situation. Take sprayed aluminum, for example, its surface will be affected by processing technology and different types of powder coatings. Although their appearance looks similar, their sticky requirements will be different. Some require high-viscosity PE protective film, some may need super-high-viscosity protective film. Photos and telephone communication are not enough to figure out the difference. When we get the protected surface sample, we could perform a series of tests (peeling force test, initial adhesion test, 70 ℃ water resistance, and high-temperature resistance ). This would help to determine the final protective film solution.

Although it will cost some time for the first cooperation, it will avoid the follow-up risks and potential replacement charges caused by inappropriate products. Please help do the protected surface sample and start our cooperation.

Leave a Reply

Want to join the discussion?Feel free to contribute!