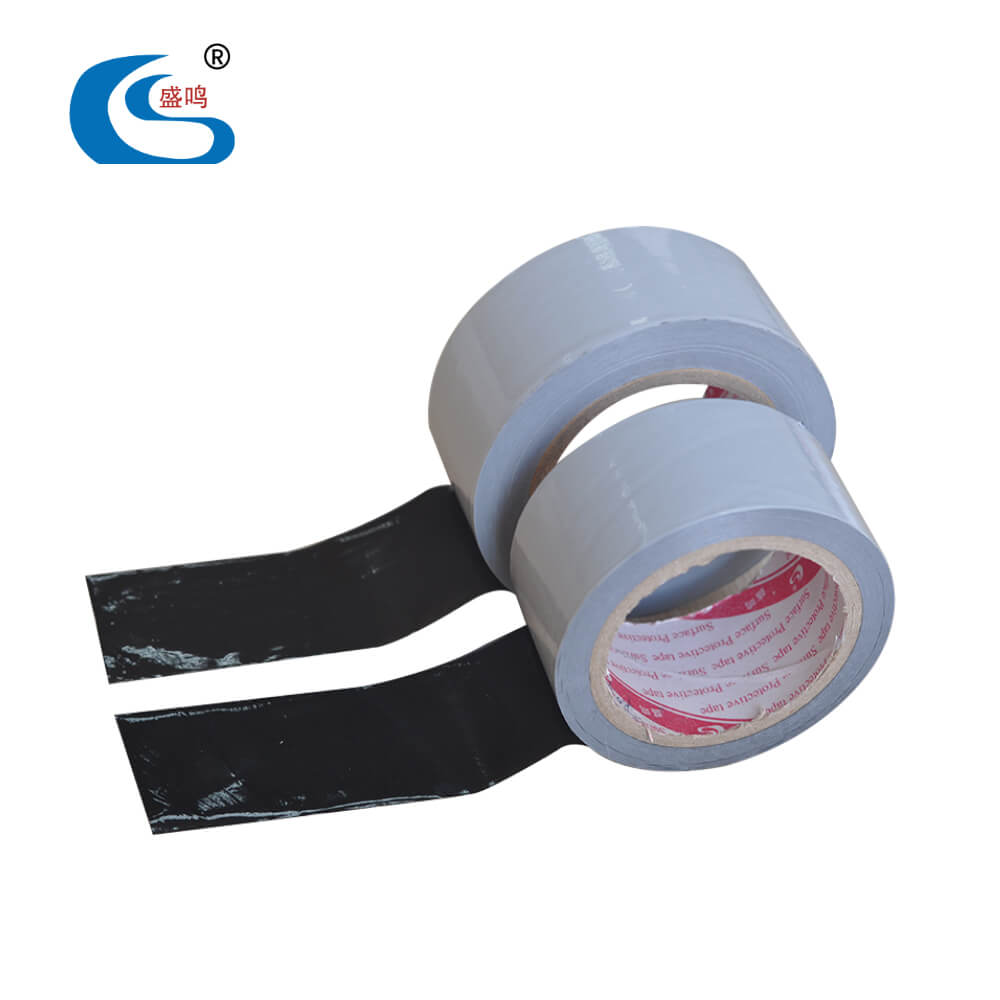

PE Protective Film for Aluminum Profile

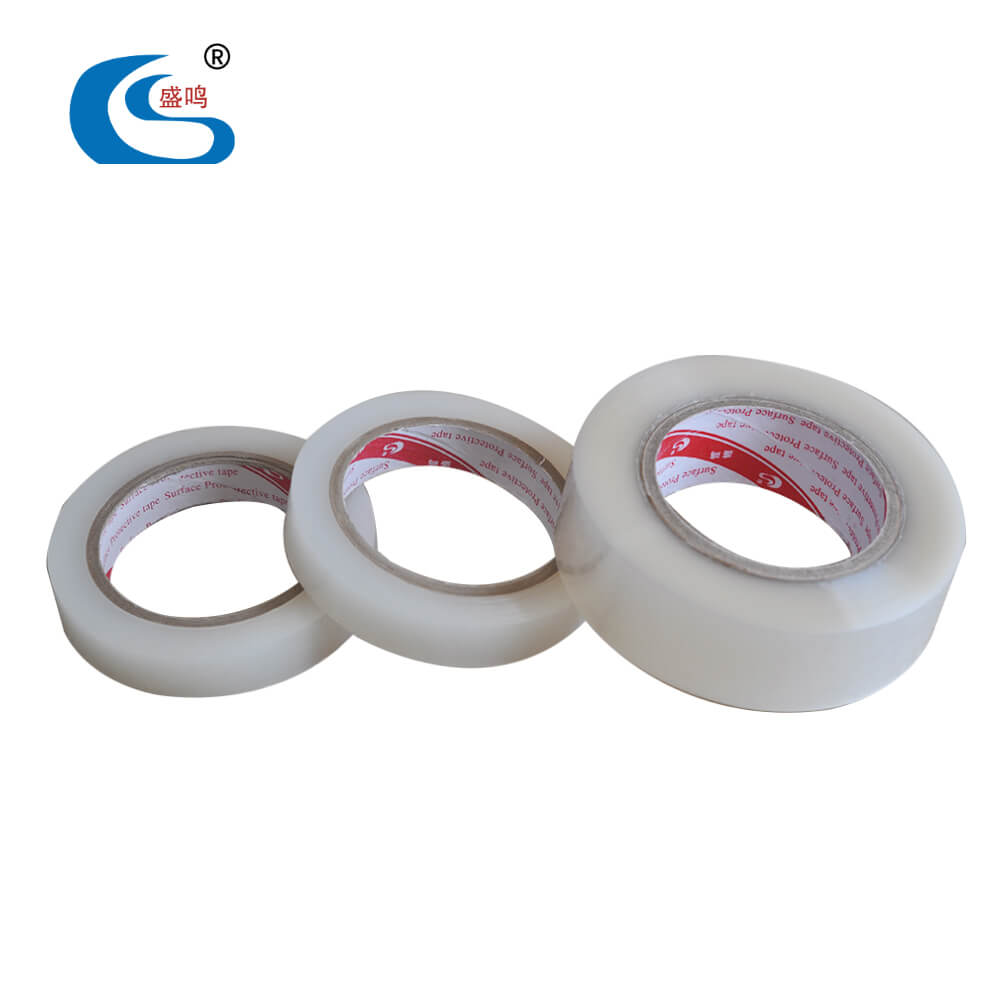

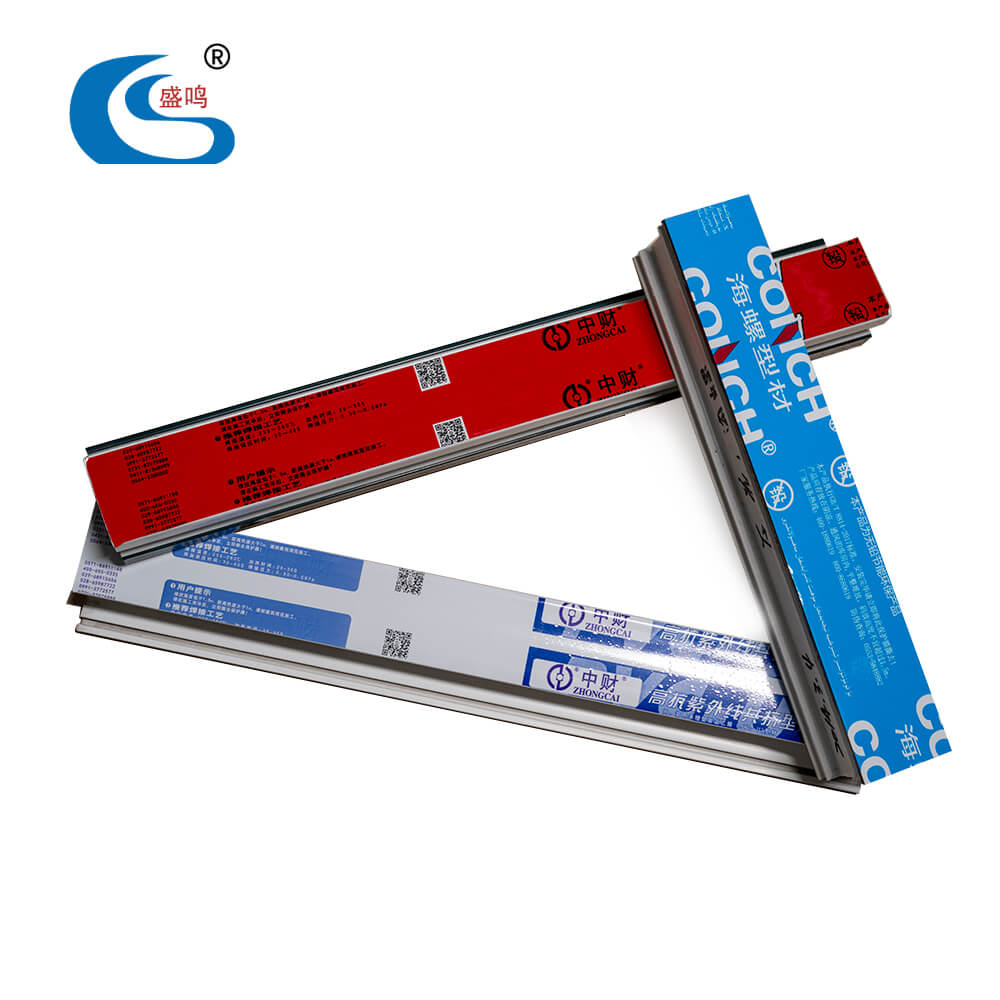

PE Protective Film for Glass

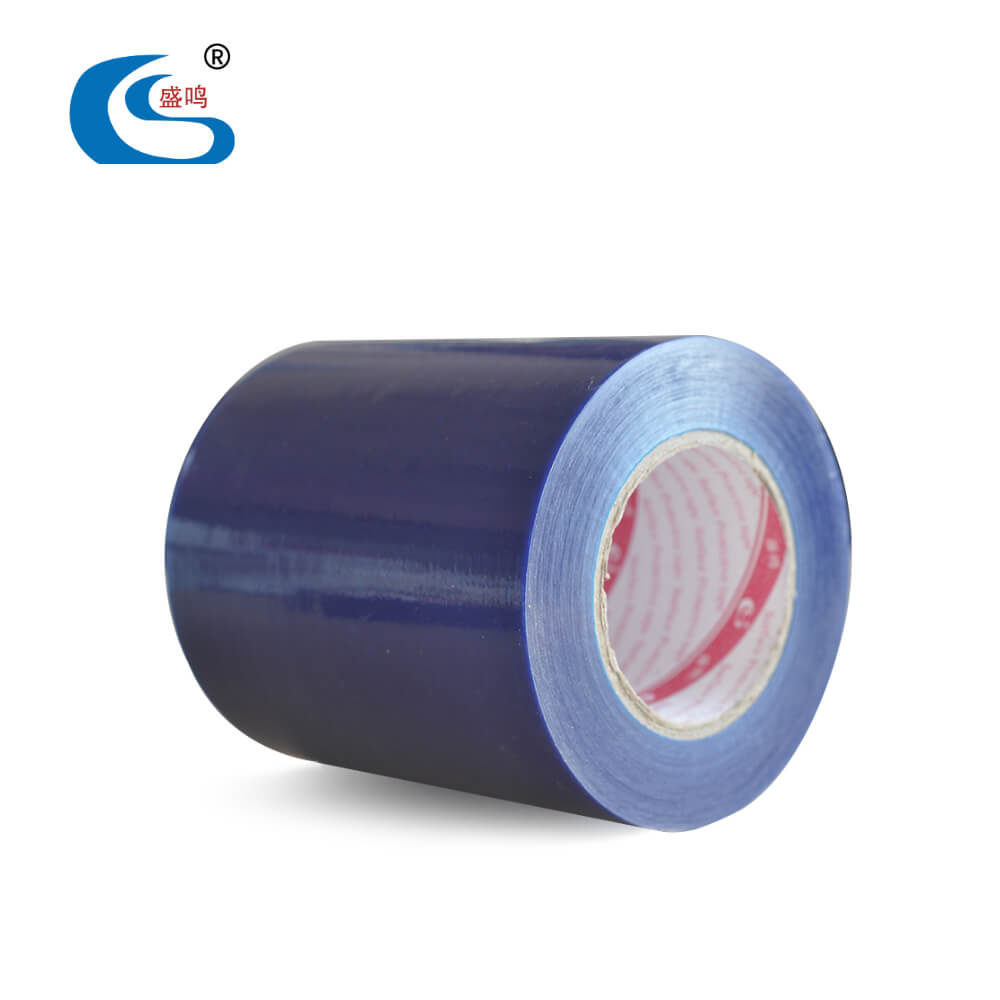

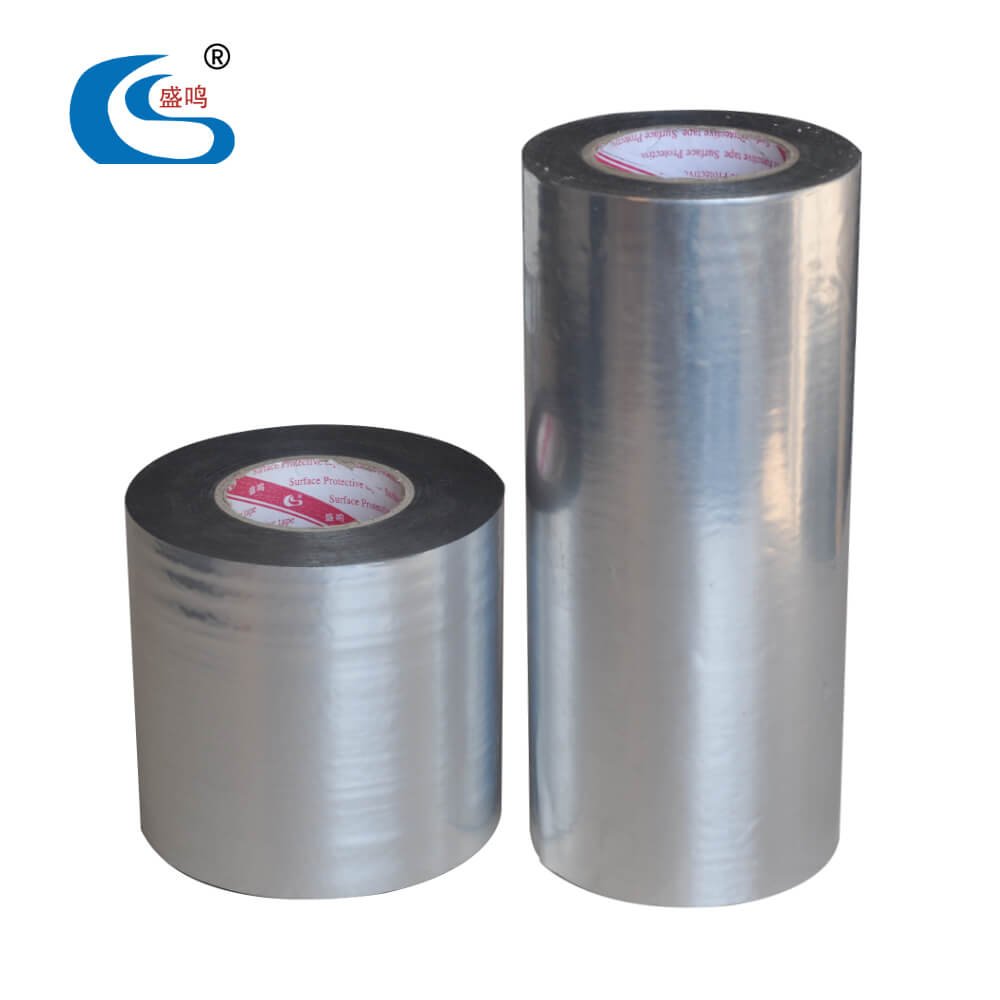

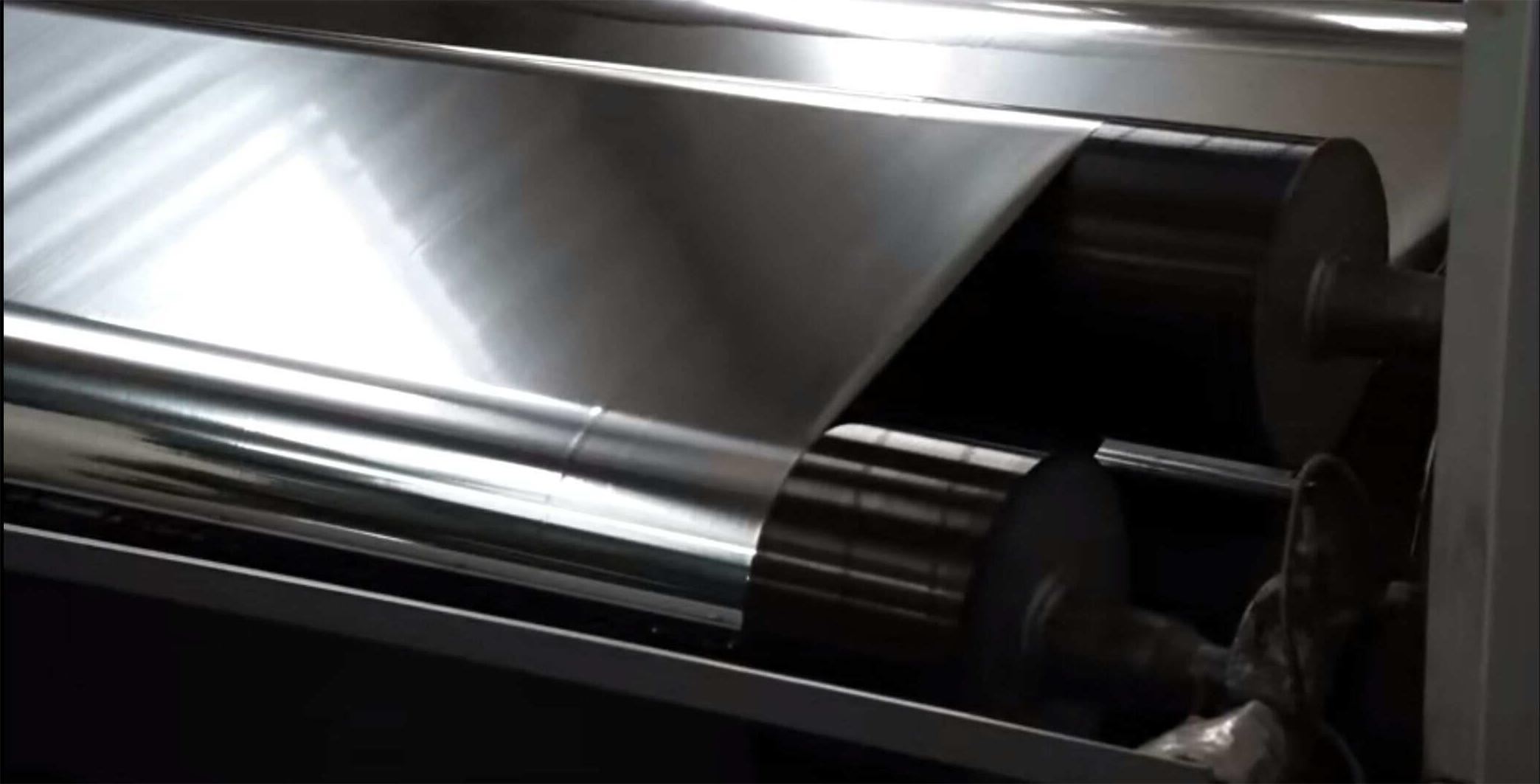

PE Protective Film for Stainless Sheet

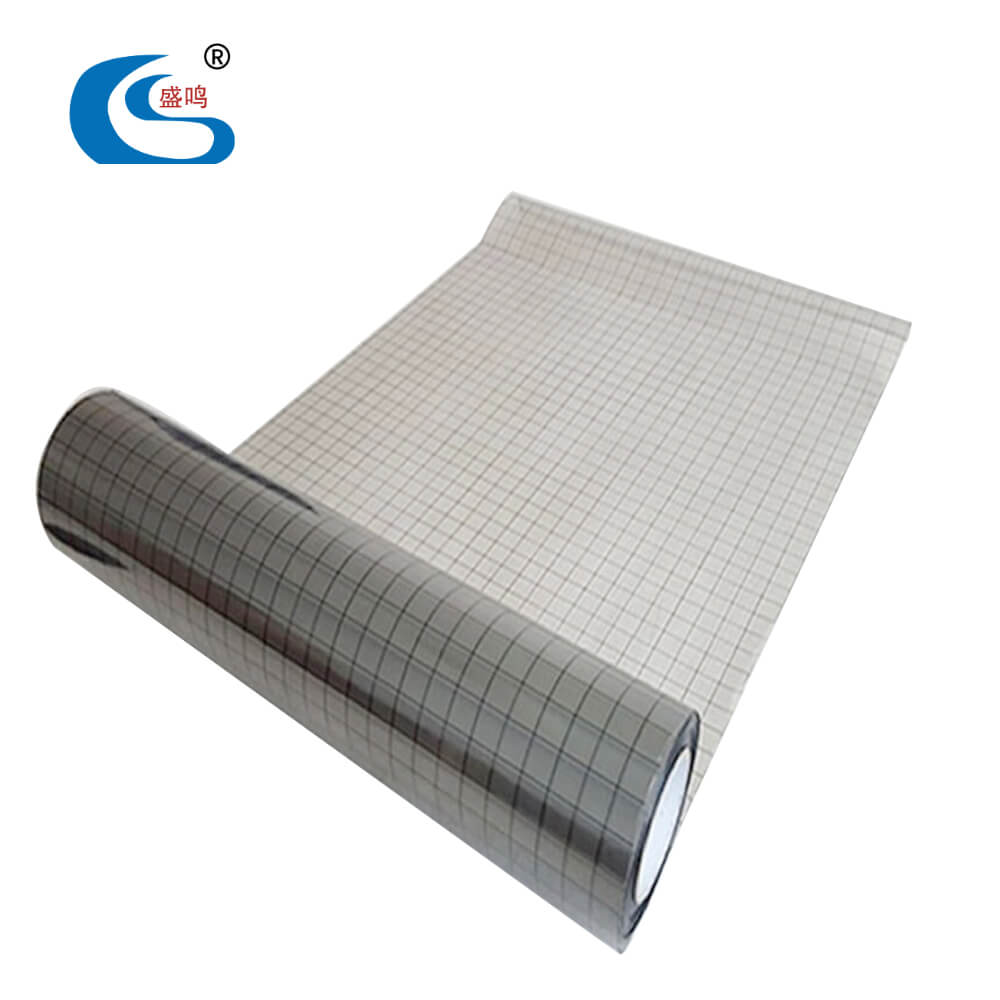

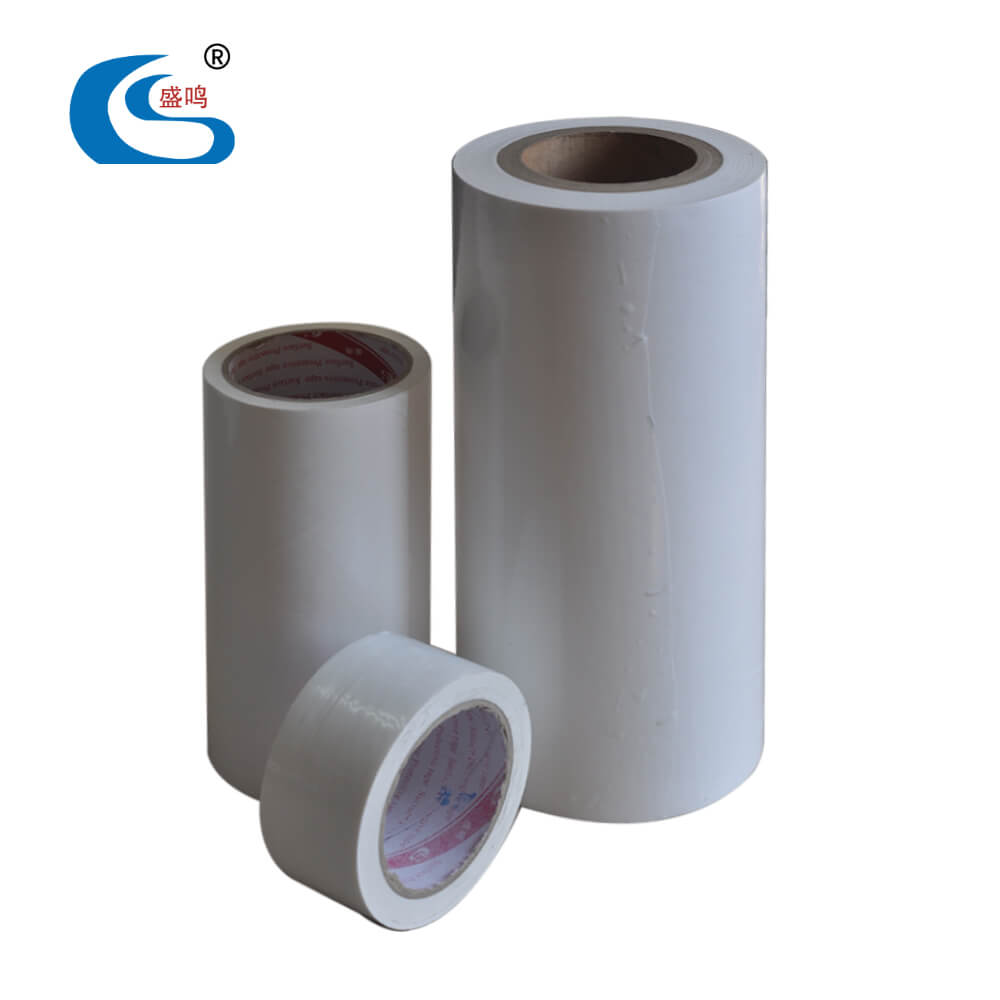

PE Protective Film for Carpet

Demand for sustainable products is growing

As of 2018, many products on the market claim to be more eco-friendly than conventional products. From sheets to containers, furniture to shoes, computers to phones, many products on the market are being advertised as being more eco-friendly.

Today’s consumers are more aware now than ever of the impact their purchases have on their health and the condition of the environment. As a result, demand for products that are safer, more sustainable, and produced with minimal impact on the environment is growing. In response to this trend, a good number of companies are incorporating bio-based ingredients into their products to put them ahead of their competitors in an increasingly growing market.

Heat waves, extreme drought, and ice caps melting at the North Pole; there seems to be no shortage of environmental and climate-related problems today. From plastic pollution to global warming and air pollution, there is a growing urgency to find sustainable and eco-friendly alternatives for everyday things that contribute to the earth’s degradation. At the center of this need is our willingness and ability to create sustainable and innovative solutions that not only serve us but contribute to a cleaner planet.

It is this quest for long-lasting solutions that has led us to create PE protective films that are eco-friendly and bio-based. They represent our dedication and a valuable contribution to combating climate change.

- Our protective film has a good climate balance.We achieve this by using renewable raw materials in the production process.

- C02 emissions are significantly lower (60%) when compared to other conventional protective films.

- Our focus on producing bio-based products does not compromise their adhesion qualities.

- Our protective films are highly effective with excellent adhesive properties, abrasion and tensile resistance.

The PET Bio-Based Protection Films

The protective from Shengming is coated by water-based/emulsion pressure-sensitive adhesives that protect products from dust, scratch, erosion, and damage. It also has excellent high and low-temperature, waterproof properties and anti-UV performance. The protective film is also water-resistant and scratch-resistant, which makes it easier to apply. Thanks to its one-step application, it’s easy to use and helps to prevent your device from getting damaged. The protective film has different adhesion levels –low, medium, and high and colors and designs. Our company’s logo can also be customized to suit your requirements, with eight possible colors.

Sustainable Surface Protection

We are not unaware of the effects of our activities as a plastic processing company on the environment, nor are we ignorant of our role and resulting responsibilities to society and the environment. The creation of our eco-friendly protective film is to contribute to positive, sustainable development. This is how we do it:

-

Improved climate protection without compromise increases sustainability

These eco-friendly films are engineered to provide you with the same levels of strength, durability, and abrasion resistance. Due to the engineering process behind the manufacturing of eco-friendly protective films, they can provide you with better levels of corrosion resistance. These eco-friendly protective films are flexible, conformable, and easier to install as well. Eco-friendly protective films are an investment that will pay off for your company and the environment.

-

Our PE films are recyclable

Our protective films are not made from recycled materials; instead, they are recyclable. This means that after use, they get a chance at a second life. The result is to reduce plastic pollution in the environment with a reduced amount of waste winding up in landfills worldwide. In addition to this, our company’s water-based acrylic pressure-sensitive adhesives deionized water instead of solvent. That means there is no solvent residue after drying. This makes our protective films safer for humans and the environment. Our company keeps looking for new and different ways to make our protective films more eco-friendly.

-

Use of emulsion PSA systems which makes our eco-friendly protective films

Our films use a self-developed water-based adhesive that is environmentally friendly. These adhesives are made from natural acrylics. The application changes depending on the surface adhesion requirements. Water-based and emulsion pressure-sensitive adhesives are a safer alternative to solvent-based glues. These types of adhesives consist of water, acrylates, and curing agent. Various pressure-sensitive adhesives are available by adjusting the ratio of pressure sensitive adhesive and curing agent. The performance of these types of adhesives is similar to solvent-based films.

PRODUCTS & SERVICES

PE Protective Film for Mirror

PET Protective Film for PVC Profile

Low-E Glass Protective Film

Pressure Sensitive Adhesive

Our company realized the importance enterprises attach importance to environmental protection many years ago. Through years of development, some efforts have been made from the following aspects.

Raw material control:

PE film is a recyclable material. We insist on using brand new raw materials and reject using recycled raw materials, which reduces waste to some extent.

The water-based acrylic pressure-sensitive adhesives developed by our company use deionized water instead of solvent, so there is no solvent residue after drying, and leaves no damage to the human body and the environment. It is an environmentally friendly product. Its ten chemical compositions meet the restrictions set out in the Amendment Directive (EU) of Annex II to the ROHS Directive 2011/65/EU. And our acrylic pressure-sensitive adhesive has strong adhesion, it could meet the same adhesion request of solvent pressure-sensitive adhesive with less use of our glue.

The raw materials can be stored only after they pass internal inspection, which reduces the loss caused by unqualified raw materials.

Equipment innovation:

Since 2020, we have introduced 3 sets of high-efficiency production equipment. Through the introduction of advanced equipment and technical renovation, product quality and production efficiency have been improved comprehensively and effectively. The improvement of the finished product rate not only reduces the loss of raw materials, reduces the discharge of industrial waste, but also reduces the use of natural gas and electric energy needed for production.

In addition, we have also purchased an RTO environmental protection device to better reduce protective film production’s impact on the environment. This RTO device almost resolved 95% of the VOC waste gas and the heat recovered could be used for further production. This leads to less use of natural gas.

Internal management:

By constantly improving the company’s management mechanism, standardizing production management processes, and strengthening the ideological education of employees, our goal is to reduce material loss caused by personal reasons.

According to the production plan, arrange the production tasks reasonably to reduce energy consumption. Reasonable off-peak power consumption in summer can not only alleviate power shortage but also avoid equipment damage under long-term high temperatures.

Industrial waste:

Our industrial waste: scrap material and activated carbon are always handled in strict accordance with the requirements of environmental protection. The improvement of product quality reduces material loss, while the use of the RTO devices completely solves the situation that activated carbon is needed to purify waste gas.

In the future, our company will continue to make our own efforts towards the early realization of the goal of carbon neutrality in our motherland.

-

Our efforts contribute to decreasing our carbon footprint

Our most important achievement and the most apparent benefit are our successes in the area of environmental protection. We have been able to take the edge off our carbon footprint by using renewable energy sources and energy-efficient products. We pride ourselves in gearing our efforts towards designing a manufacturing system and process that is highly efficient, thus reducing the negative impact on the environment. As previously mentioned, our bio-based protective films are made from recyclable material, so the waste of natural resources during production is somewhat minimized. Paying close attention to these aspects of production ensures that our carbon footprint decreases.

Protective films are an investment that will pay off for both you and the environment. While there may not be any legal requirement to purchase bio-based products, consider this your contribution to addressing social issues and improving the livelihood of communities and individuals. In addition, each purchase of these recyclable, eco-friendly protective films contributes to reducing your carbon footprint, saving natural resources, and lowering the amount of waste that ends up in landfills. These, in turn, contribute to a cleaner earth.

-

Conclusion

Our eco-friendly film is eco-friendly and comes in a max of eight different colors and designs, and is 100% recyclable. We are committed to offering customized protective film solutions to our customers while contributing our effort to environmental protection.